November 7, 2023

6 Good 3d Printing Fixing Guides" Fabbaloo

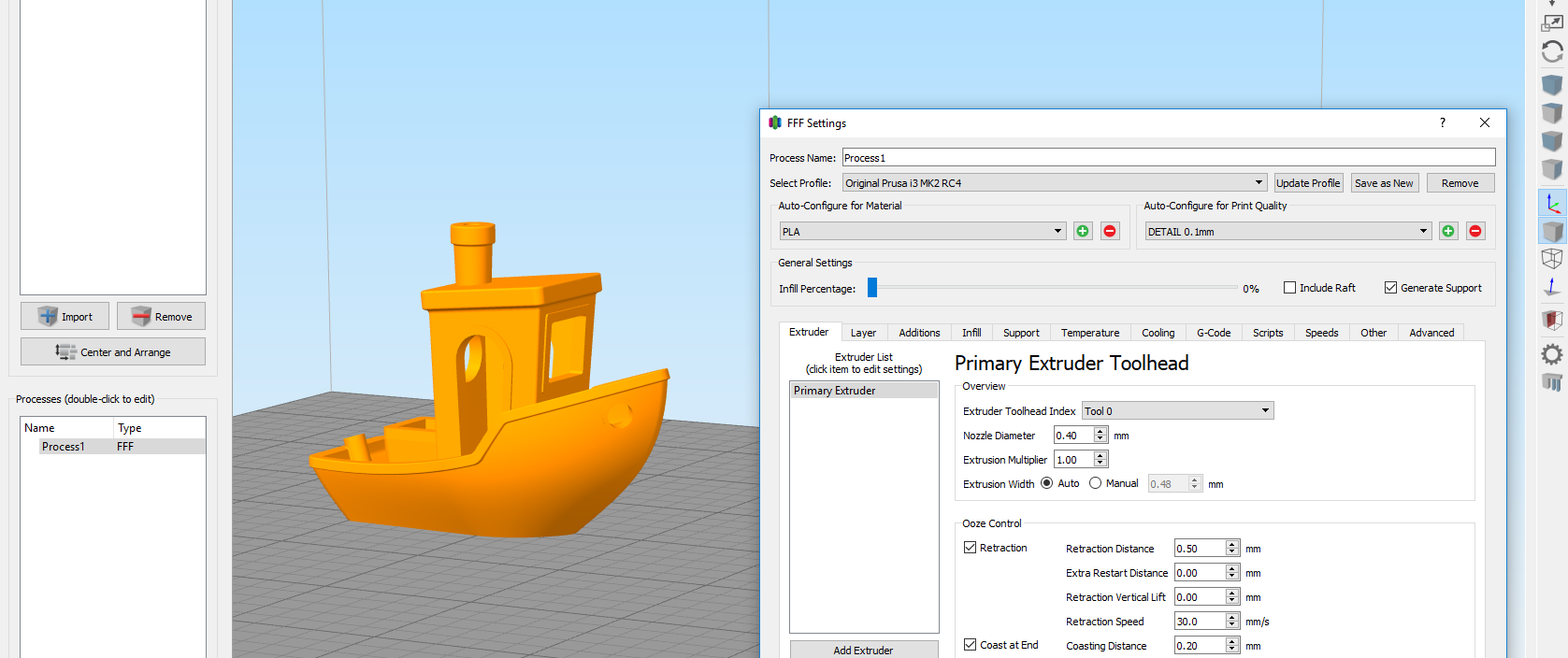

3d Printing Troubleshooting Guide It is one of the most typical 3D printer issues that you all have actually experienced. It do without stating that if the very first layer is not protect, the remainder of the print will certainly fail. As a result, settling this concern ends up being much more vital. Nevertheless, the issue is not too challenging to fix, as well as by recognizing the causes, each one of you can prevent initial layer bond issues.What are the typical 3D printing troubleshooting troubles?

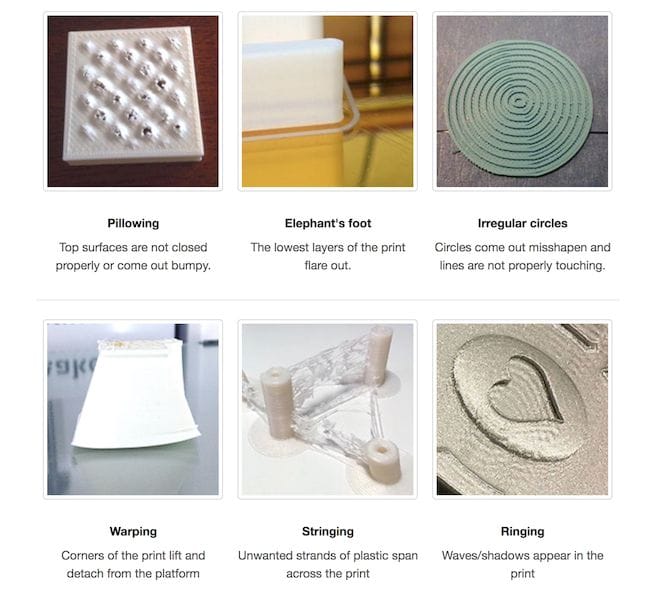

- Not Squeezing out at Start of Publish. Printer does not squeeze out plastic at the beginning of the print.Not Sticking to the Bed.Under-Extrusion. Over-Extrusion.

- Gaps in Leading Layers.Stringing or Oozing.Overheating.Layer Shifting. Size.

- One attribute to think about when

- creating your item is it's scale.The resolution.

- During additive manufacturing, the resolution describes the thickness of each layer of product being'applied.Wall thickness.The orientation.The selection of

- material.Design equilibrium. When a PLA filament absorbs moisture, it swells up, increasing the danger of extruder jams. Moisture likewise triggers PLA to produce prints with bubbles and voids externally, therefore ruining your prints

- .

Fragile Filament

There is a noticeable scrape on the leading layer that is not a line from oozing filament. Reducing the infill overlap amount in your slicer will additionally assist. Crinkling as well as harsh corners is really easy to spot as well as looks rather the mess contrasted sideways of the print. The weight of the subsequent layers crushes the reduced layers that never ever had a chance to totally harden.- If the worth of the 'infill overlap' setting is an absolutely no and even isn't evaluated all, then the issue will likely show up.

- Clean the poles and also transform the oil, and the problem may be resolved.

- More than likely, the 3D printing surface area of that layer is over-extruded and that's why the nozzle scraped it in the action.

- Issues with stringing as well as exuding make your 3D prints look unshaven, like a spider attempting to develop a web between different components of the structure.

- Even prior to the clog appears throughout upkeep you can generally locate particular symptoms such as old filament that is currently carbonized showing up inside the nozzle.

Filament Not Feeding Correctly

The default values of acceleration and jerk are typically respectable, yet if they are established high for one reason or another, you can try decreasing them to see if it aids deal with the problem. The supply springs that include your 3D printer aren't normally the best high quality, so this is a very beneficial upgrade. You can also include braces to maintain your printer in position, in addition to put an Anti-Vibration Pad under the printer. Make certain you periodically inspect the nozzle and also, if it shows up harmed, alter it. Unclean bed - Dust, particles and oily fingerprints will certainly prevent the attachment in between bed as well as filament. The majority of bed surfaces take advantage of cleansing making use of Isopropyl alcohol and paper towel every couple of prints. Please examine if IPA is safe for your bed to stay clear of harming the surface area. Slow it down - The initial layer really gains from a much slower feedrate to aid the filament stick. Most slicers have a speed setting just for layer one, so you can make sure great adhesion without slowing down the succeeding layers. If the nozzle is also much from the bed, the initial layer effectively prints in mid air, with the filament not crushing into the bed surface area and also for that reason not adhering appropriately.Motor Is Wildly Reversing As Well As Forth Even With No Filament Filled:

Layer binding concerns will certainly additionally occur as an outcome of this. In this case, try boosting the temperature a little as well as keeping an eye on the results until suitable layer bonding is attained. The majority of the moment, you count on downloaded and install layouts without verifying the version or whether it is printable. It is constantly a great concept to ascertain the created G-code and also sneak peek the version in the slicer software to make certain that the design can be published.Driven by Quality: Enabling 3D Printing in Industrial Serial Production – AMS Speaker Spotlight - 3DPrint.com

Driven by Quality: Enabling 3D Printing in Industrial Serial Production – AMS Speaker Spotlight.

Posted: Sat, 04 Feb 2023 08:00:00 GMT [source]

Social Links