November 22, 2023

New Overview Makes It Very Easy For Any Individual To Boost Their 3d Print Top Quality Software Talk Production

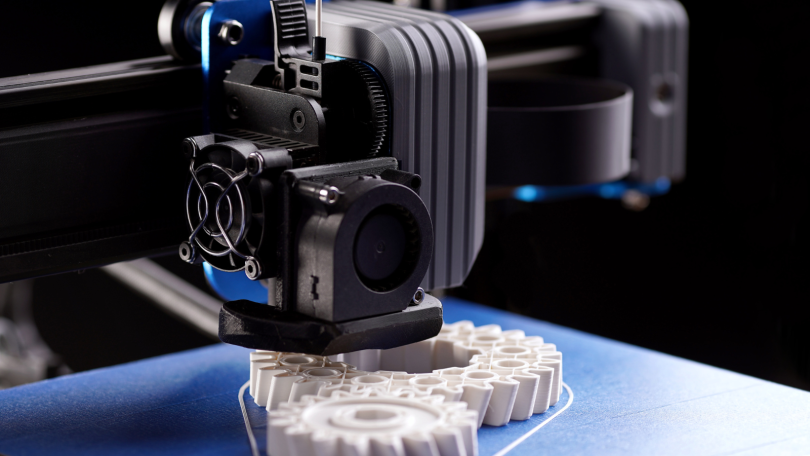

3d Printing Troubleshooting: All Problems & Options You're below due to the fact that you've either just had a complete 3D print failing, or your prints aren't rather best. We do not opt for less than ideal, so we do not anticipate you to either. Have you ever experienced a layer change in your 3D prints? Discover how to determine as well as fix layer shift in 3D prints prior to they become a trouble. This week's option is the massive Articulated Dragon by Cults factor MCGYBEER and also published to range by Metalhead Printing.Ash’s Declassified Survival Guide to Running a 3D Printing Makerspace - 3DPrint.com

Ash’s Declassified Survival Guide to Running a 3D Printing Makerspace.

Posted: Tue, 03 Jan 2023 08:00:00 GMT [source]

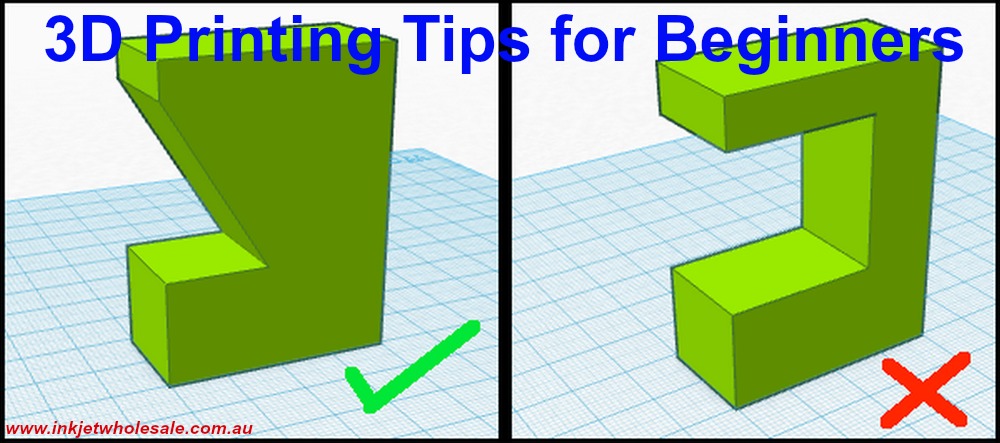

Summary Of Services: Improperly Built Bridges

In some cases something like an ABL probe will certainly be fitted immediately, before the user recognizes how to manually level the bed. The thrill to update denies the user of learning the fundamentals necessary for reliable and reliable long term procedure. To prevent dampness shop your filament dry, this is why we at rigid.ink provide special Mylar resealable bags with each order. If your printer is enclosed, open up all doors, side panels or top covers to keep the ambient temperature down. Even the most effective fans mishandle if all they're doing is relocating warm air around. Overhangs are where you're printing a slanted surface area without any assistance under. I would certainly recommend taking the PTFE tube out and having a proper check out it. After taking a look at it, you may simply need to clear out a clog, or change the PTFE tube completely if it's harmed. Below is a photo of Plethora in Cura on an XYZ Calibration Dice. You can select a Raft simply by going into Cura, scrolling to Construct Plate Attachment in the settings food selection, then choosing Boating, same with a Brim. Keeping your printer in excellent working order goes a long means in getting the very best outcomes feasible.- It decreases exactly how swiftly the design cools off given that the temperature level around the extruded filament is greater.

- Examine the rigidness and appropriate alignment of your printer frame.

- Some extra lines of filament can create your print to look different than it should.

- The initial point to do if you experience over extrusion is to decrease your printing temperature so filament doesn't flow through so easily.

Printer Troubleshooting Overview

Stringing is a common concern that people face when 3D printing. It's a print blemish that generates lines of strings across a 3D print. They need to generate a relatively low/deep sound when plucked.3D Printing News Unpeeled: Metal 3D Printing Pen, Shell Wall 3D Printing - 3DPrint.com

3D Printing News Unpeeled: Metal 3D Printing Pen, Shell Wall 3D Printing.

Posted: Mon, 27 Mar 2023 07:00:00 GMT [source]

What are the usual 3D printing troubleshooting troubles?

- Not Extruding at Start of Print. Printer does not extrude plastic at the beginning of the print.Not Staying with the Bed.Under-Extrusion. Over-Extrusion.

- Spaces in Leading Layers.Stringing or Oozing.Overheating.Layer Shifting. Size.

- One function to think about when

- producing your thing is it's scale.The resolution.

- During additive manufacturing, the resolution describes the thickness of each layer of product being'applied.Wall thickness.The orientation.The selection of

- material.Design balance. When a PLA filament absorbs wetness, it inflates, enhancing the risk of extruder jams. Moisture additionally creates PLA to create prints with bubbles and also voids externally, consequently destroying your prints

- .

Social Links