November 7, 2023

3d Printing Tips For Newbies: Exactly How To 3d Print A Realistic Looking Sculpture- Community Stories Learn And Write About 3d Printing

30 Vital 3d Printing Suggestions For Newbies Best Results Experiment to see what works best for a specific part as well as printer. Any individual dealing with 3D versions, publishing figurines and also collectibles, or beneficial things for a house might maximize a free STL editor. Such software application assists you to edit and also fix STL data as well as boost (personalize, range up/down) your favorite projects.Electroplating 3D Prints – All You Need to Know - All3DP

Electroplating 3D Prints – All You Need to Know.

Posted: Wed, 07 Jun 2023 14:08:41 GMT [source]

Consider Your Product Requires

However, the user interface between the two layers is a weak point, and also 3D prints damage at these interfaces. An additional way of enhancing 3D prints is by utilizing the best infill pattern. Infill patterns collaborate with infill density, and also they function as an internal support framework for 3D prints. They likewise add some tightness to the part and protect against wall surface contortion. On exactly how to make solid 3D prints using infill patterns, you ought to use a dense infill pattern ranging from 30-50%. Utilizing a thin layer will certainly lead to far better bond as well as density between subsequent layers, which reinforces 3D printed components.Why are my 3D prints so negative?

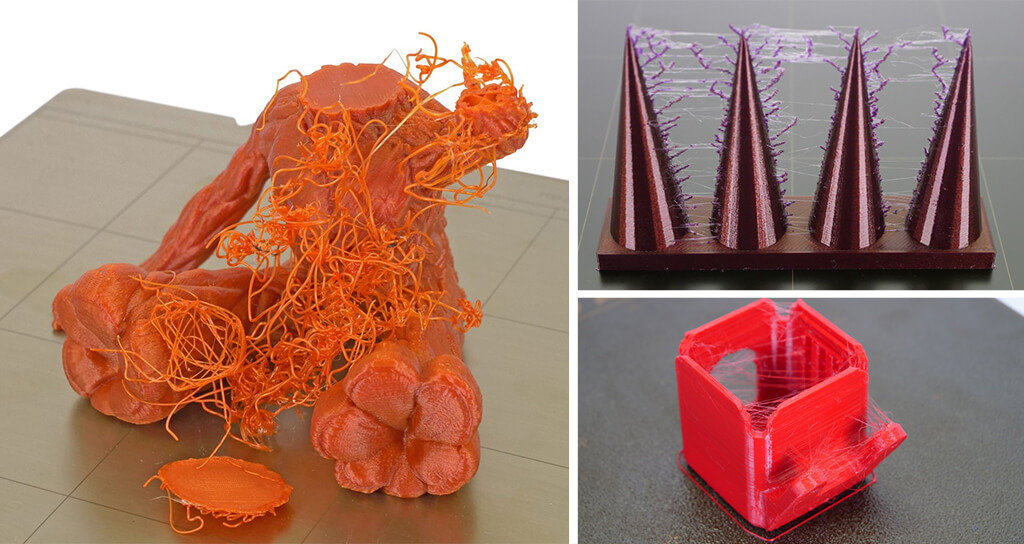

The most typical cause is just that the print just does not bond to the surface of the print platform. The filament needs a textured base in order to stick, so to solve the problem you''ll need to develop a much better bonding surface. An unlevel print platform can be an additional significant concern.

Minimize Initially Layer Rate For Better Bond

I like it and use it on a regular basis, yet it requires a great deal more job to make it stable so it does not collapse at the most awful feasible moment. Superficial understanding contour, especially for anyone who already has some programming experience. Plus, a well developed manuscript permits individuals to quickly change any kind of wanted quality of the part simply by altering variables as well as seeing it instantaneously 3D made. They don't need to know anything at all regarding OpenSCAD itself. You do not need to make use of much as a little of the hardener can coat and also reinforce the print. Using epoxy finish on the 3D print makes it more powerful and also offers it with a clear as well as shiny surface.- Currently I likewise got Simplify 3D as well as upgraded my head.

- Wayne State University's industrial layout professor, Claas Kuhnen, gives a review of creating a natural layout procedure and addresses typical design-to-print concerns in this video.

- In 3D printing, there are some materials that are known to be weak.

- Velocity setups affect how swiftly the print head reaches its top speed.

- If the materials you intend to make use of are basically different-- hence, the maker needs to heat up or cool off to a various temperature level-- the process could take permanently.

What Is Warping And Exactly How Can You Prevent It?

Marlin Firmware is most likely one of the most preferred printer firmware presently available, as well as it has actually a function called Linear Advance. This attribute regulates the filament pressure inside your hotend as well as readjusts it during printing to offer you with much better top quality prints. Most of the printers generate the very best top quality when models are published slowly, however there are decreasing returns publishing slower than ~ 25-30 mm/s. The Minimal Printing Speed ought to be set as close as possible to the external layer printing speed to avoid inconsistent layers. With the bed leveled and the Z offset dialed in, you require to check if the extruder steps are correctly set, and the extruder is pushing the proper quantity of plastic trough the nozzle. You most likely know that my slicer of option is IdeaMaker since it enables me to adjust firmware worths straight from the slicer without messing around with re-compiling the firmware. The tornado rolled over and also luckily I didn't loose power. My bed is glass, with a layer of Scotch brand tape and wiped down with massaging alcohol. This benefits me on EVERY print, so I do not mess with it. I respect the people that can publish directly on glass, carbon or Kaplon tape, I just can not. I like this machine as well as covered it for years for National Geographic. I used all my brand-new techniques as well as instantly I had this develop with 20 components that published perfectly every single time. As an example, if you need a component to be blue, you could have the component dyed rather than repainted to reduce time and money. You can find out more about the information of just how to prepare STL data in our tutorial. Don't add to the problem even if you don't have the determination to stay clear of some affordable enjoyment. That stated, I have actually already taken on techniques that virtually remove this trouble in my jobs. You might also have them make a space in Floorplanner for a slightly different angle of 3D as well as layout. After your lesson one week you can also allow the students vote on which object you want to produce with each other following week. After that you can enjoy a tutorial by HL Mod Technology initially and from that lead them through producing whatever they choose at a slower pace.Social Links