November 7, 2023

Advanced 3d Printing Tips

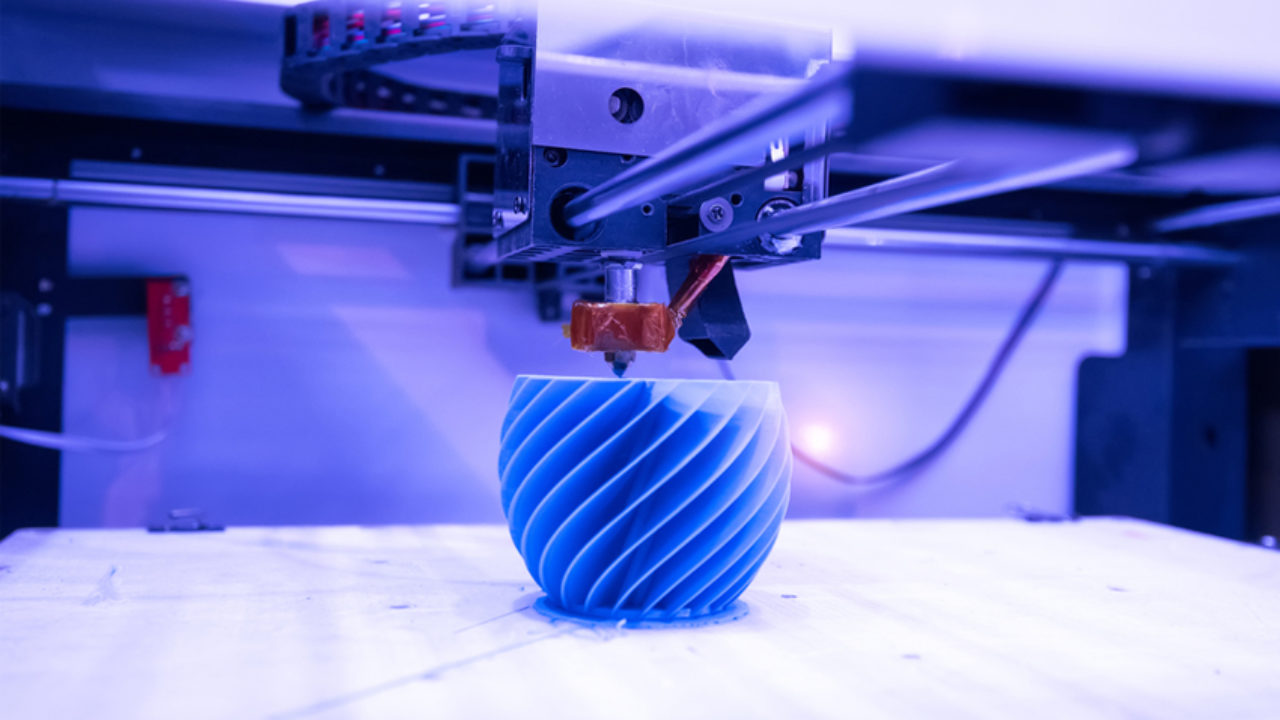

What Is 3d Printing And What Is Additive Manufacturing? Hp ® Main Website The researchers evaluated the printer with as many as three different syringes, each loaded with material colored a various color. The new style enhances an approach of 3D printing produced by DeSimone and also his coworkers in 2015 called constant liquid user interface manufacturing, or CLIP. CLIP publishing looks like it belongs in a sci-fi flick-- a rising system efficiently draws the object, apparently completely formed, from a thin swimming pool of resin. The material at the surface area is hardened into the appropriate shape by a series of UV photos projected with the swimming pool, while a layer of oxygen stops healing at the end of the pool and creates a "dead area" where the resin remains in fluid type. By comprehending as well as implementing the appropriate post-processing methods, designers, developers, and also manufacturers can open the full capacity of 3D printing, creating top notch components that are suitable for a broad variety of applications.What are the 3D printing methods?

There are a number of sorts of 3D printing, that include: Stereolithography (SLA) Selective Laser Sintering (SLS) Integrated Deposition Modeling (FDM).

Careful Laser Sintering (sls):

You purchase a new print-- this time around, you require it to be functional and also cosmetically finished. Your relied on 3D printing partner, Stratasys Direct Production, publishes up your part in Molten Deposition Modeling, hand sands it down and ships it back to you done in the span of five service days. Today, 3D printing a very early phase layout and also re-printing it overnight is practical and also affordable thanks Visit the website to rapid prototyping or 3D printing platforms like PolyJet and also Stereolithography. Where sustains are called for greatly depends upon the material, build process and also construct resolution, among other aspects. Insufficient direct exposure may lead to not enough smoothing, while extreme direct exposure can cause the part to become warped or deteriorated. Normally, the vapor smoothing process takes in between 10 and also 60 minutes, depending upon the product, the solvent, as well as the desired finish. [newline] FFF is the most optimal method of fast prototyping of parts which must maintain the standard tolerance. The method has actually been widely utilized in creating building or model mock-ups. At one factor he mentions 11 suggestions, yet the title has 10 as well as we needed to extend to get to that number considering that some of them have some overlap. However, he likewise reveals some C-clips, a method to include wall surfaces for stamina, as well as printing spur equipments.Securing new metal 3D printing technology that drives the renaissance of the manufacturing industry! - Newswise

Securing new metal 3D printing technology that drives the renaissance of the manufacturing industry!.

Posted: Mon, 27 Mar 2023 07:00:00 GMT [source]

Voxeljet 3d Printing Systemsincrease Your Productivity

Similarly to SLM, EBM equipments set you back upwards of 1M to set up and require a devoted technician to run. This year a various, though similarly pioneering, construction product is readied to bring attention to the community, which is 20 miles north of Manchester and whose latest claim to fame is being trash-talked in a 1989 advert for milk. On Charter Street, on a patch of disused land owned by the council, there are plans to construct 46 net-zero-carbon homes, varying from single-bedroom houses to four-bed homes, all occupied by low-income families or army professionals. The houses will be made not from Nori blocks, yet from 3D-extruded concrete. When the advancement is complete, possibly in late 2023, it will be the largest printed structure facility in Europe. Survey participants selected the capability to supply parts much faster as the leading benefit of additive production.- Because of rough handling conditions of SFF approaches (e.g. warmth, organic solvent), biochemical particles are not normally integrated directly right into the scaffold.

- What is 3D printing as well as where are their feasible applications and what is it in fact with the ability of?

- The low-carbon housing was published by 2 large integrated arms from a combination of in your area sourced dirt as well as water as well as fibers from rice husks and also a binder.

- One method you can require to help you choose based upon the key constraints of your project.

Printed Electronics

When we consider what products are currently using compared to what they want to utilize, plastics stay the leading selection. However, the wish to utilize nearly all various other materials surpasses the existing use. Many significantly, the need to utilize glass exceeds existing usage by 20%; need to use ceramics goes beyond usage by 14%; as well as interest in metals surpasses existing use by 10%. Based upon these findings, it will certainly be interesting to see just how additive product usage advances in another 2 years. Because 2019, we've seen a remarkable increase in the 3D printing product types that companies are utilizing.Has the 3D printing revolution finally arrived? - The Guardian

Has the 3D printing revolution finally arrived?.

Posted: Sun, 12 Mar 2023 08:00:00 GMT [source]

Social Links