November 22, 2023

Industrial 3d Printing & 3d Printer Manufacturer

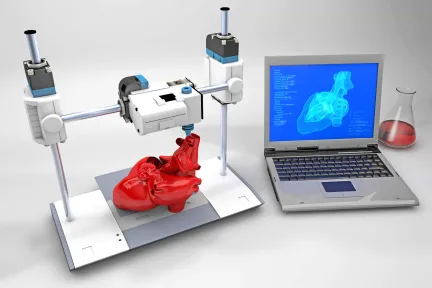

What Is 3d Printing And Also What Is Additive Manufacturing? Hp ® Main Site • Merged Deposition Modeling-- FDM printers thaw a plastic filament and deposit it onto a build plate layer by layer. FDM is a simple, budget-friendly 3D printing modern technology appropriate for educational and also house use. On the one hand, the extremely individualized production of one-of-a-kind products and also tiny as well as really tiny batches will once more ended up being effective and economically intriguing. On the various other hand, durable, high-performance 3D production systems are penetrating areas that till recently were booked for traditional producing processes.What is the strongest 3D printing technique?

Polycarbonate. According to several manufacturers and customers, polycarbonate (PC) is considered the strongest consumer filament around. PC can produce very high-strength parts when printed correctly with an all-metal warm end as well as an enclosure.

Industrial Composite 3d Printers

Additionally, materials such as solvents may produce unstable organic compounds, and some processes might advertise emission of unstable natural compounds. Although the initial steps have been made almost 3 decades back, 3D building printing has actually battled to reach out for years. The initial modern technologies to achieve some limelights were Shape Crafting as well as D-Shape, with a couple of occasional posts in 2008-- 2012 as well as a 2012 television report. D-Shape has also been included in an independent docudrama dedicated to its designer Enrico Dini, called "The man that publishes houses".Industrializing 3D printing MIT News Massachusetts Institute of ... - MIT News

Industrializing 3D printing MIT News Massachusetts Institute of ....

Posted: Mon, 28 Nov 2022 08:00:00 GMT [source]

Instances Of The Sectors Voxeljet Industrial 3d Printing Business Collaborates With

The ability to 3D print useful electronic devices systems will certainly open several chances for smart components as well as items. With Binder Jetting 3D printing modern technology, and also the tool-free manufacturing of molds and cores for classic steel casting procedures, we are opening up brand-new horizons for the factory industry. Without any constraints on individualization, lightweight building and construction as well as demanding or intricate geometries. And also not to fail to remember with an excellent prospective for expense optimization in the production procedure. Voxeljet also supplies additive manufacturing worldwide as an on-demand service.- The spreading surface is after that five-axis grated, removing roughly 5mm of wax, to produce a high-grade mold and mildew (with roughly 20-micron surface area roughness).

- For metal SLS components, polishing can be employed to attain a mirror-like coating.

- HSS Product Network-- Evidence of Concept HDPE Together with Fraunhofer IPA we have qualified the polymer HDPE for additive production within our HSS Product Network.

3D Printing Advanced Technology Center Opens in Japan to Spur ... - All3DP

3D Printing Advanced Technology Center Opens in Japan to Spur ....

Posted: Wed, 26 Apr 2023 07:00:00 GMT [source]

Social Links