November 22, 2023

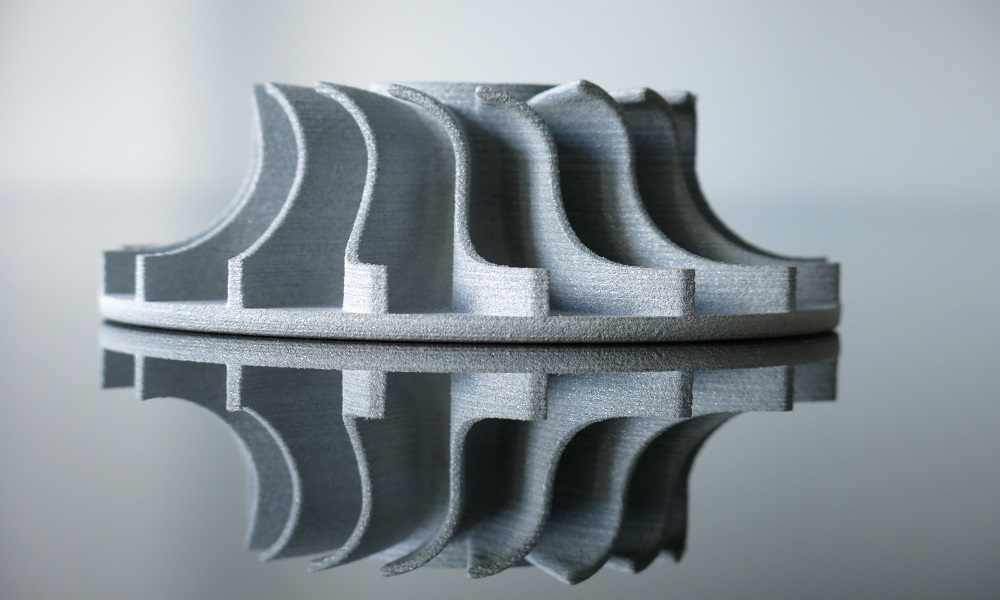

Kinds Of 3d Printing In Steel

Protected 3d Printing The Brand-new Disruptive Modern Technology And Also Watch The Marketplace Expand The process repeats till the maker yields a completed build of finished components. Cable DED machines make use of a laser to thaw feedstock in an extremely comparable fashion to their powder DED family members-- nevertheless, their feedstock is metal cord instead of blown powder. It's a particular niche innovation used with larger construct quantities and faster print times at the cost of precision and also quality. Therefore, Wire DED components are made to be considerably larger and less accurate than powder bed equipments. These equipments set you back numerous million bucks per unit and are extremely uncommon in the area.What are the 3D printing strategies?

There are numerous sorts of 3D printing, which include: Stereolithography (RUN-DOWN NEIGHBORHOOD) Selective Laser Sintering (SLS) Fused Deposition Modeling (FDM).

An Intro To 3d Printing As Well As Additive Manufacturing Processes, Materials As Well As Benefits

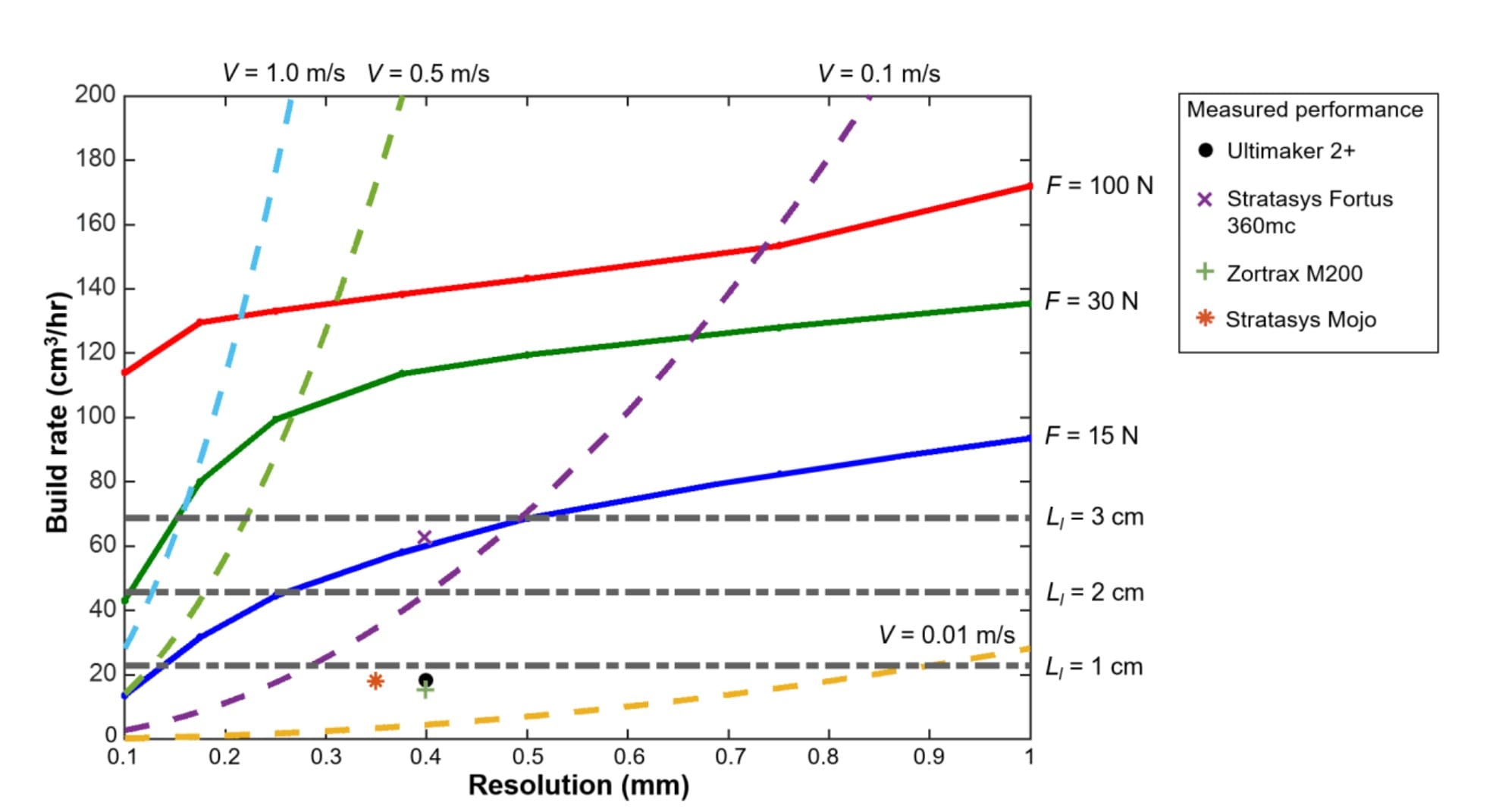

The technology mainly uses a specific amount of product needed for the specific part, otherwise than in CNC approaches which generate high losses of the material we make use of. Practically every industry is being interfered with by the switch from analog to electronic procedures, and manufacturing is no various. 3D printing and additive manufacturing are helping to bring chance, adaptability, and also efficiency to manufacturing procedures. What began as a specific niche and futuristic technology has today end up being extensively used and also even ubiquitous. Today, using 3D printing has actually grown to the factor where almost all significant producers are including or seeking to include it into their style or manufacturing processes.Industrializing 3D printing MIT News Massachusetts Institute of ... - MIT News

Industrializing 3D printing MIT News Massachusetts Institute of ....

Posted: Mon, 28 Nov 2022 08:00:00 GMT [source]

What Are The Guidelines For Generating Top Notch 3d Printing?

HA particles were covered with a water-soluble PVA through spray-drying or physical mixing. Williams et al. fabricated PCL scaffolds with permeable architecture and also enough mechanical residential properties for bone cells design applications. What are the primary distinctions in between careful laser sintering, HP's Multijet Fusion and voxeljet's High Speed Sintering?- The voxeljet family of items cover the entire variety from portable 3D printers to fully automated 3D printing systems.

- Distributed 3D printing may encourage much more self-dependent as well as lasting cultures gradually.

- • Electron Beam Of Light Melting-- EBM utilizes an electron beam of light to thaw metal powder together layer by layer.

- Created at the Massachusetts Institute of Modern Technology, Three Dimensional Publishing produces 3D structures by inkjet printing liquid binder option onto a powder bed [8-10]

- The modern technology primarily utilizes an exact amount of product required for the specific component, or else than in CNC methods which generate high losses of the material we use.

Assistance Elimination

The original SLA rasters a HeCd-laser beam to spatially control the polymerization of photocurable material in 2D patterns. After each layer is healed, the platform with the healed structure connected after that decreases in the bottom-up approach and another layer of uncured fluid material spreads over the top. For the top-down method, light is predicted onto a transparent plate originally positioned near the bottom of the vessel holding the liquid material.Metso, a renowned industry leader, has recently secured substantial ... - SteelGuru

Metso, a renowned industry leader, has recently secured substantial ....

Posted: Fri, 09 Jun 2023 02:31:54 GMT [source]

Social Links