November 7, 2023

3d Printing Layout Tips

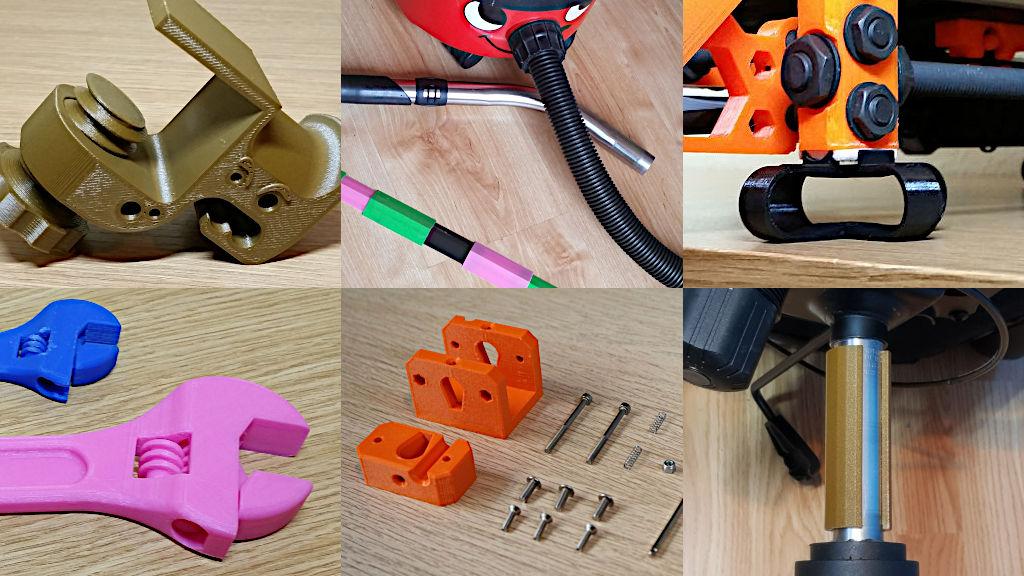

30 Essential 3d Printing Suggestions For Beginners Finest Outcomes The nozzle temperature level, and there might be several nozzles, impacts print top quality. If it is too hot, there will certainly be filament strings between spaced components. On high pieces, high temperatures usually thaw the leading layers and also warp the final object. If you are printing a taller item, add a one-centimeter dice on the opposite side of the printer's construct plate that is opposite side to get rid of the hot nozzle from the component. If strings of filament appear between structures, consider utilizing a shield structure or wall. The simplest means to improve 3D print quality is to make certain the bed is leveled and nozzle distance is appropriately set.How do you obtain great PLA prints?

Adjust Your Extruder E-steps And Flow Rate For Much Better Circulation

All 3D printers can efficiently print elements with wall densities above 0.8 mm. Are you new to designing components for 3D print production or need a refresher on vital style components? This write-up gives the key style aspects for producing electronic versions for 3D printing, regardless of the additive manufacturing procedure. If creating a large part, save both time and material by considering different infill patterns that use much less material. Hollow, geometric shapes characterize infill patterns with the density and form of the infill impacting the toughness of the final printed material. Printing with a smaller sized nozzle takes more time, so it's only worth your while if you are manufacturing an extra ornamental item and also have a lot of time. However, you must take care as this setting is directly pertaining to extrusion, i.e., a huge change in line width can bring about over and under extrusion. Nonetheless, most individuals change the circulation rate to repair other 3D printing issues such as the lack of ability to achieve volumetric flow as well as to boost accuracy. Theoretically, having a 100 infill thickness should make your 3D print really solid. Nevertheless, practically most designers have observed that anything past 70% has a lower influence on reinforcing the 3D print. Instead, there is an incredible rise in filament usage, printing time, price, and worry on the 3D printer. Even if you do not think https://large-format-printers.b-cdn.net/Printing-Glossary/screen-printing/3d-printer-filament-ideal-filament-for-3d-printer-snapmaker.html it's part of the problem, clarify it anyways.Including 3d Printing In Different Subjects

The slicer assumes that the nozzle is correctly machined, and also the hole is reduced to the exact dimension. You may find yourself discovering that your printed versions have a great general external finish, yet there are some layer variances at some times. Or you may see some under extruded sections in your infill. This is usually half the rate of the print rate I use for the inner walls, however this may require to be changed according to your equipment.Liqcreate engineers share best practice on how to 3D print with ... - 3D Printing Industry

Liqcreate engineers share best practice on how to 3D print with ....

Posted: Mon, 05 Sep 2022 07:00:00 GMT [source]

Social Links