November 7, 2023

Brand-new 3d Printing Process Is Quicker And A Lot More Precise Than Conventional Techniques Sciencedaily

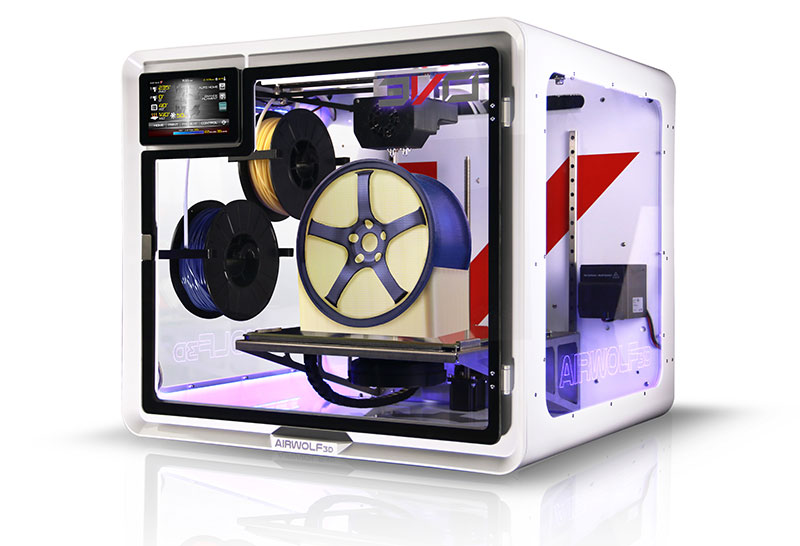

3d Printing Modern Technologies: Kinds And Advantages As background has actually taught us, the Razor-Razorblade design functions just when there is a strong IP protection system applied against cloning, counterfeiting, reproducing, and also imitating disposables. The DS28E15 DeepCover protected authenticator IC is the ideal course for selling more 3D printers. Maxim has a long record, 20+ years of R&D, in making embedded protection solutions to shield diverse end markets including monetary, print consumables, clinical consumables, computer, video gaming, power metering. Adage's competence with crypto formulas, complex IC-level physical protection applications (e.g., progressed die-level physical security), as well as tailored IC product packaging continue to be key to helping for consumers secure their R&D investments.What is the advancement of 3D printing?

Developments in 3D printing have actually made it less complicated for designers as well as engineers to customize jobs, develop physical prototypes at different ranges, and also generate frameworks that can't be made with more typical production methods.

What Abilities Are Needed For 3d Printing?

Additionally, materials such as solvents might release unpredictable organic compounds, and some procedures may advertise emission of unpredictable organic substances. Although the initial steps have actually been made almost three decades back, 3D construction printing has battled to connect for years. The initial innovations to achieve some limelights were Contour Crafting and D-Shape, with a couple of sporadic write-ups in 2008-- 2012 and also a 2012 television record. D-Shape has actually also been featured in an independent docudrama committed to its creator Enrico Dini, called "The male who publishes houses".5 ways advanced metal additive manufacturing can revolutionise the ... - Australian Manufacturing

5 ways advanced metal additive manufacturing can revolutionise the ....

Posted: Wed, 24 May 2023 07:00:00 GMT [source]

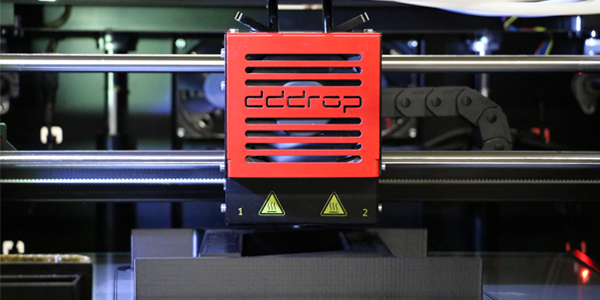

Universal Binder Jetting

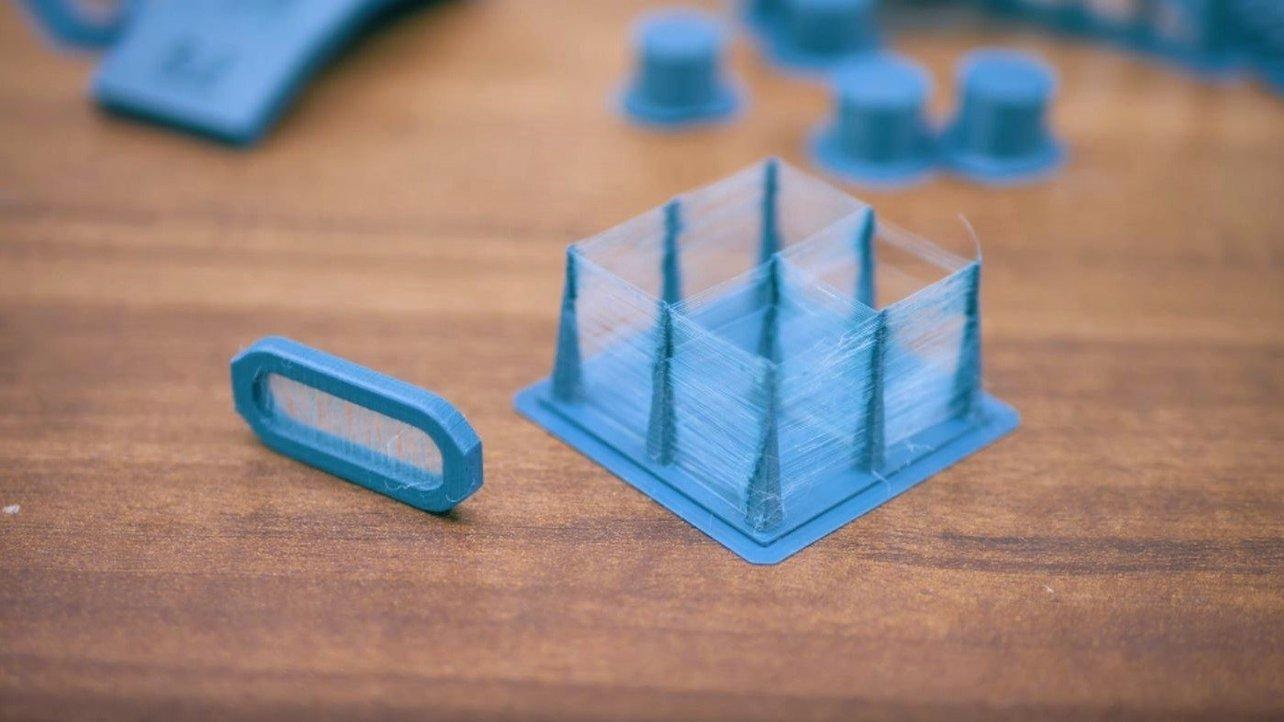

This reorganization can cause a much more crystalline structure, which translates to enhanced mechanical performance. Right away after printing, the components are coated in uncured material, and this excess material requires to be eliminated to ensure a tidy surface area coating. Normally, the parts are submerged in a solvent, such as isopropyl alcohol or a proprietary cleaning remedy, to liquify and also eliminate the recurring material. Correct safety preventative measures and also individual safety equipment ought to be made use of when taking care of chemicals throughout this procedure.Open Source Melt Electrowriting 3D Printer Could Democratize Advanced Techniques - 3DPrint.com

Open Source Melt Electrowriting 3D Printer Could Democratize Advanced Techniques.

Posted: Fri, 17 Feb 2023 08:00:00 GMT [source]

- The 3D PolyJet innovation is just one of one of the most exact 3D printing innovations on the planet.

- An instance of a demand is anatomic issues in the craniomaxillofacial complicated caused by cancer, trauma, and also genetic issues.

- Download the 2021 survey record to learn more about the existing state of the worldwide 3D printing market.

- However, once the assistances are gotten rid of, they can leave marks or marks on the surface of the part.

Social Links