Demystifying the Welding Process: A Beginner's Handbook

# Demystifying the Welding Process: A Beginner's Handbook

**Demystifying the Welding Process: A Beginner's Handbook**

# **Types of Welding**

Welding encompasses various techniques tailored for different applications:

**MIG Welding**

Metal Inert Gas (MIG) welding is widely favored for its speed and adaptability. It involves feeding a continuous wire electrode into the weld pool, making it ideal for beginners.

**TIG Welding** Tungsten Inert Gas (TIG) welding offers precision and control but requires more skill than MIG. It’s perfect for projects where aesthetics matter, like custom fabrications.

**Arc Welding**

Arc welding uses an electric arc between an electrode and the workpiece to generate heat. It’s versatile but requires good technique to avoid defects.

**Plasma Cutting** This technique employs a plasma torch to cut through electrically conductive materials with ease. It's invaluable in metal fabrication.

# **Mobile Welding Services**

With mobile welding services, professionals come directly to your location. This convenience can save time and effort, particularly in urgent situations like auto welding repair.

# **Welding Certifications Explained**

Gaining certifications showcases your skills and knowledge in welding processes. Various organizations offer certifications that enhance credibility and job prospects.

# **Welding Techniques Comparison Guide**Here’s a quick comparison of popular welding techniques:

| Technique | Best For | Skill Level | |----------------|-----------------------------------|------------------|

| MIG | Quick projects | Beginner | | TIG | Precision work | Intermediate |

| Arc | Heavy-duty repairs | Advanced | | Plasma Cutting | Cutting metal | Intermediate |

# **Energy Efficient Welding Tips**

Adopting energy-efficient practices not only reduces costs but also minimizes environmental impact. Consider using inverter-based machines that consume less power while providing superior performance.

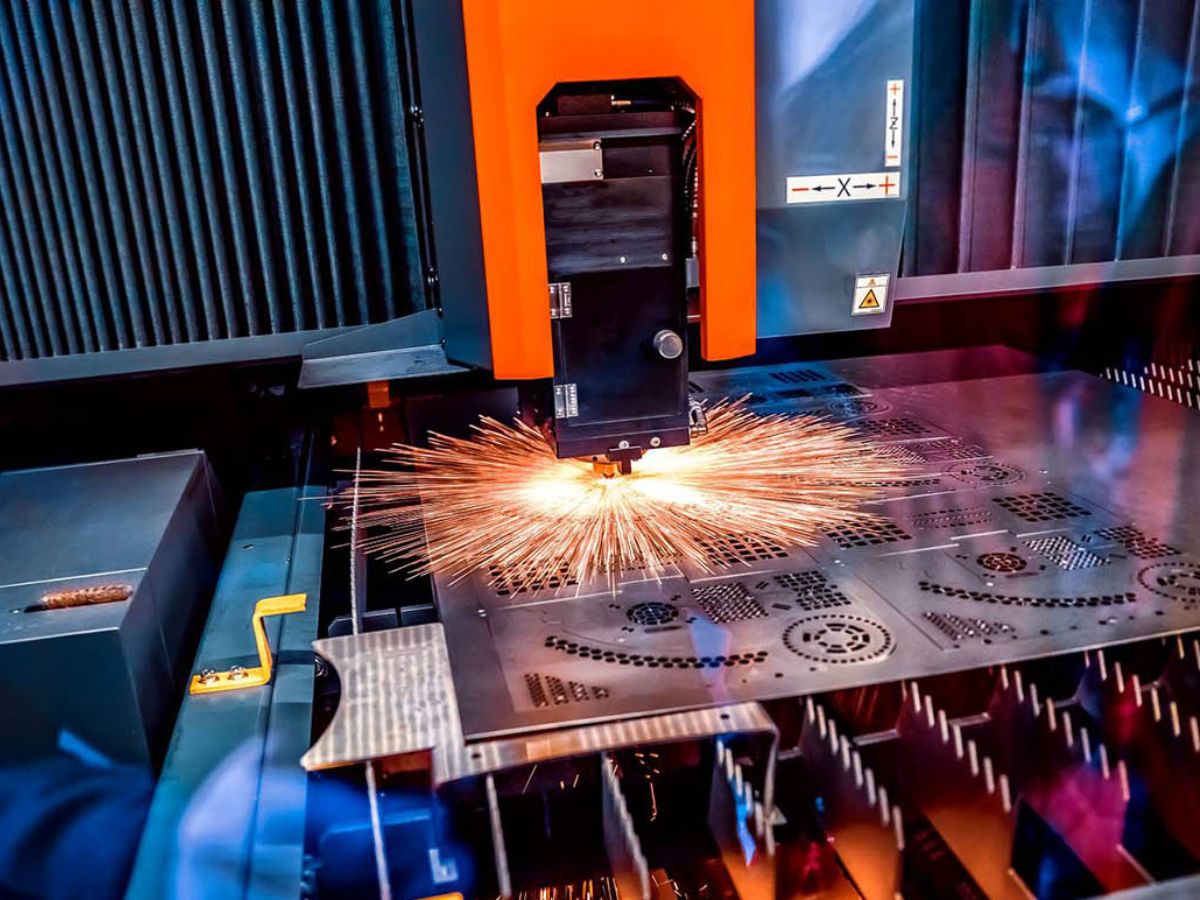

# **Latest Welding Technology Advancements**

The world of welding technology is ever-evolving. Innovations like robotic welding systems are becoming increasingly popular due to their efficiency and consistency.

# **Customer Experience Stories in Welding Projects**Hearing real-life experiences can provide insights into what to expect: > "I had my porch railing custom welded last summer – it was seamless! The welder understood my vision perfectly." – Sarah J., satisfied customer

# **Seasonal Welding Tips and Tricks**

Weather affects welding conditions significantly:

- In colder months, preheating metal can prevent cracking. - Always ensure proper ventilation during hot weather when working with fumes.

# **Types of Welding Joints and Their Uses**

Choosing the right joint type ensures structural integrity: - Butt Joint: Used for joining two pieces end-to-end.

- Corner Joint: Ideal for adding strength at corners.

Understanding these joints aids in selecting suitable methods based on project requirements.

# FAQs about Demystifying the Welding Process 1. **What is the best type of welding for beginners?**

MIG welding is often recommended due to its simplicity and ease of use.

2. **How do I choose between MIG or TIG?** If you're looking for speed over precision, go with MIG; if detail matters more, opt for TIG.

3. **Are there specific safety precautions I should take?**

Yes! Always wear PPE including gloves, helmets with proper lenses, and protective clothing.

4. **Can I learn welding online?** Absolutely! Many resources offer online courses ranging from beginner classes to advanced techniques.

5. **What certifications should I pursue?**

Look into AWS (American Welding Society) certifications as they are widely recognized within the industry.

6. **How important are inspections?** Very important! Inspections help identify potential issues before they become major problems affecting safety or quality.

pre1/##