Introduction

Fabrication techniques play a crucial role in transforming unconventional materials into functional and innovative products. This how-to guide explores various methods and processes involved in fabricating unconventional materials, providing valuable insights for designers, engineers, and manufacturers.

Understanding Unconventional Materials

Before diving into fabrication techniques, it is essential to have a clear understanding of unconventional materials. These materials are non-traditional and often possess unique properties that make them suitable for specific applications. Examples include bioplastics, smart textiles, graphene, and aerogels.

Bioplastics

Bioplastics are derived from renewable sources such as corn starch, sugarcane, or vegetable oils. Fabrication techniques for bioplastics involve extrusion, injection molding, and 3D printing.

Smart Textiles

Smart textiles are fabrics embedded with electronic components or sensors. Fabrication techniques for smart textiles include weaving, knitting, and printing conductive inks onto the fabric.

Graphene

Graphene is a single layer of carbon atoms arranged in a hexagonal lattice. Fabrication techniques for graphene involve chemical vapor deposition, mechanical exfoliation, and epitaxial growth.

Aerogels

Aerogels are lightweight materials with high porosity. Fabrication techniques for aerogels include sol-gel synthesis, supercritical drying, and freeze-drying.

Fabrication Techniques

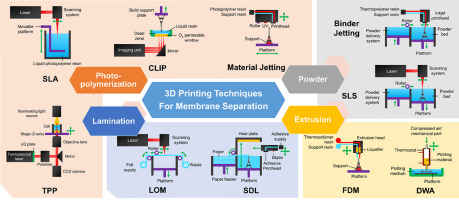

Additive Manufacturing

Additive manufacturing, also known as 3D printing, is a versatile fabrication technique for unconventional materials. It involves building objects layer by layer using computer-aided design (CAD) models. This technique allows for complex geometries and customization.

Composite Fabrication

Composite fabrication involves combining two or more materials to create a new material with enhanced properties. Techniques such as hand lay-up, resin infusion, and filament winding are commonly used for fabricating composites.

Summary

Fabrication Techniques for Unconventional Materials: A How-To Guide is a comprehensive resource for individuals interested in exploring the possibilities of working with unconventional materials. The guide covers a wide range of materials, including but not limited to biodegradable polymers, recycled textiles, natural fibers, and composite materials.

The guide begins by introducing the concept of unconventional materials and their growing importance in the field of fabrication. It highlights the unique properties and sustainability benefits of these materials, emphasizing the need for innovative fabrication techniques to harness their full potential.

Throughout the guide, readers will find detailed step-by-step instructions for various fabrication techniques. These techniques include cutting, shaping, joining, and finishing unconventional materials. Each technique is accompanied by clear illustrations and practical tips to ensure successful outcomes.

Additionally, the guide provides insights into the tools and equipment required for working with unconventional materials. It covers safety precautions and best practices to ensure a safe and efficient fabrication process.

Whether you are interested in creating eco-friendly furniture, fashion accessories, or experimental art installations, this guide will equip you with the knowledge and skills needed to bring your ideas to fruition. By embracing unconve address ntional materials and mastering the fabrication techniques outlined in this guide, you can contribute to a more sustainable and innovative future.

- Q: What is the purpose of “Fabrication Techniques for Unconventional Materials: A How-To Guide”?

- A: The purpose of this guide is to provide instructions and guidance on various fabrication techniques specifically tailored for unconventional materials.

- Q: Who can benefit from this guide?

- A: This guide is beneficial for researchers, artists, designers, and anyone interested in exploring and working with unconventional materials in their projects.

- Q: What are unconventional materials?

- A: Unconventional materials refer to any materials that are not commonly used in traditional fabrication processes, such as recycled materials, organic matter, or unconventional composites.

- Q: Are the fabrication techniques suitable for beginners?

- A: Yes, this guide provides a range of techniques suitable for beginners, as well as more advanced techniques for those with prior experience in fabrication.

- Q: Are the fabrication techniques cost-effective?

- A: The cost-effectiveness of the techniques may vary depending on the specific materials used. However, the guide includes techniques that aim to minimize costs and utilize readily available resources.

- Q: Can I use these techniques for large-scale projects?

- A: Yes, the techniques described in this guide can be adapted for both small-scale and large-scale projects, depending on the requirements and resources available.

- Q: Are safety precautions mentioned in the guide?

- A: Yes, the guide emphasizes the importance of safety precautions and provides recommendations for handling and working with unconventional materials in a safe manner.

- Q: Is there information on troubleshooting common issues during fabrication?

- A: Yes, the guide includes troubleshooting tips and solutions for common issues that may arise during the fabrication process with unconventional materials.

- Q: Can I access additional resources for further exploration?

- A: Yes, the guide provides references to additional resources, such as books, articles, and websites, that can further enhance your understanding and exploration of fabrication techniques for unconventional materials.

Welcome to my website! My name is Noah Embry, and I am a passionate Dental Public Health Specialist with a strong interest in prototyping essentials, 3D printing techniques, design software reviews, and custom fabrication tips. I am thrilled to share my knowledge and expertise in these areas with you.