Introduction

3D printing technology has revolutionized the way we manufacture and create objects. From simple prototypes to complex designs, this innovative process has opened up a world of possibilities. In this blog post, we will explore the latest advancements in 3D printing, uncovering the cutting-edge techniques and materials that are pushing the boundaries of this rapidly evolving field.

2. Bioprinting: Revolutionizing Healthcare

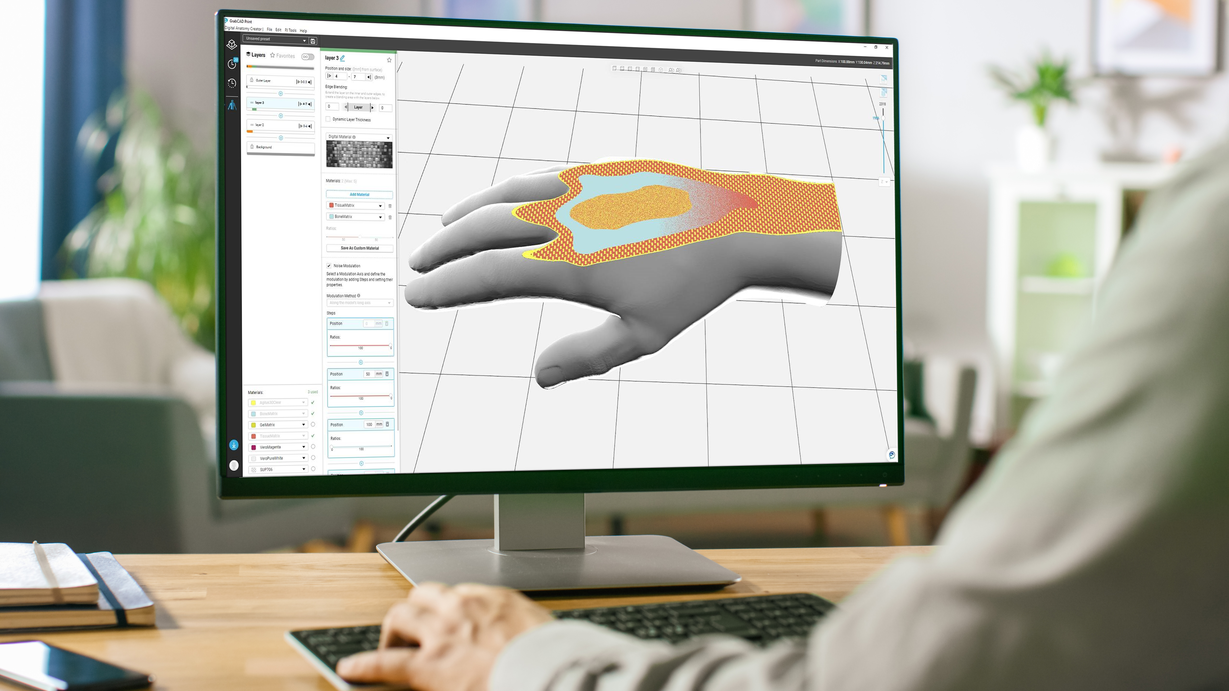

One of the most exciting developments in 3D printing is bioprinting, which involves the creation of living tissues and organs. This technology has the potential to transform the healthcare industry by providing personalized organ transplants, reducing waiting times, and eliminating the risk of organ rejection.

2.1 Organ Transplants Made Easier

With bioprinting, organs can be created using a patient’s own cells, eliminating the need for donors and the risk of rejection. This breakthrough could save countless lives and revolutionize the field of organ transplantation.

2.2 Advancements in Tissue Engineering

Bioprinting is also being used to create artificial tissues for research purposes. Scientists can now print tissue models that closely mimic human organs, allowing for more accurate drug testing and reducing the need for animal testing.

3. Aerospace Industry: Pushing the Boundaries

The aerospace industry has embraced 3D printing to create lightweight and complex parts for aircraft and spacecraft. This technology has significantly reduced manufacturing costs and improved overall performance.

3.1 Additive Manufacturing in Aerospace

By using 3D printing, aerospace engineers can create intricate designs that were previously impossible with traditional manufacturing methods. This has led to the development of lighter and more fuel-efficient aircraft, reducing carbon emissions and improving sustainability.

3.2 Rapid Prototyping and Customization

Another advantage of 3D printing in the aerospace industry is rapid prototyping. Engineers can quickly create and test multiple iterations of a part, saving time and resources. Additionally, customization is easier than ever, allowing for tailored components that meet specific requirements.

Summary

3D printing has come a long way since its inception. Today, researchers and engineers are constantly pushing the limits of this technology, introducing new techniques and materials that enhance the capabilities of 3D printers. From bioprinting human organs to printing intricate architectural models, the applications of 3D printing are expanding rapidly.

In this blog post, we will delve into some of the most exciting innovations in 3D printing. We will explore the use of advanced materials such as carbon fiber composites and metal alloys, which enable the creation of stronger and more durable objects. Additionally, we will discuss the emergence of multi-material and multi-color 3D printing, allowing for the production of complex and visually stunning designs.

Furthermore, we will examine the advancements in bioprinting, a field that aims to create functional human tissues and organs using 3D printing technology. This breakthrough has the potential to revolutionize healthcare, offering personalized organ transplants and reducing the need for traditional donor organs.

Lastly, we will touch upon the concept of 4D printing, where objects printed in 3D can self-assemble or change shape over time. This emerging field has implications in various industries, including robotics, aerospace, and architecture.

Join us on this journey as we explore the latest innovations in 3D printing and witness the incredible possibi try this web-site lities that lie ahead.

- Q: What is 3D printing?

- A: 3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects by layering materials based on a digital model.

- Q: How does 3D printing work?

- A: 3D printing works by slicing a digital model into thin layers, then printing each layer one by one using a 3D printer. The printer deposits material layer upon layer until the object is fully formed.

- Q: What materials can be used in 3D printing?

- A: Various materials can be used in 3D printing, including plastics, metals, ceramics, resins, and even food and biological materials.

- Q: What are the latest innovations in 3D printing?

- A: Some of the latest innovations in 3D printing include multi-material and multi-color printing, faster printing speeds, improved resolution and accuracy, and the ability to print complex geometries and intricate designs.

- Q: What are the applications of 3D printing?

- A: 3D printing has a wide range of applications, including rapid prototyping, manufacturing customized products, creating medical implants and prosthetics, architectural modeling, artistic creations, and even printing organs and tissues for medical purposes.

- Q: What are the advantages of 3D printing?

- A: Some advantages of 3D printing include faster production times, cost-effectiveness for small-scale production, customization and personalization options, reduced material waste, and the ability to create complex and intricate designs that are difficult to achieve with traditional manufacturing methods.

- Q: Are there any limitations to 3D printing?

- A: Yes, there are some limitations to 3D printing. These include limited material options compared to traditional manufacturing methods, slower production times for large-scale production, the need for skilled design and programming expertise, and the high cost of industrial-grade 3D printers.

Welcome to my website! My name is Mason Ringrose, and I am a passionate and dedicated professional Print Management Software Developer. With a strong background in advanced printing technologies, 3D printing innovations, and sustainable printing, I am excited to share my knowledge and expertise with you.